MIL-DTL-46506E

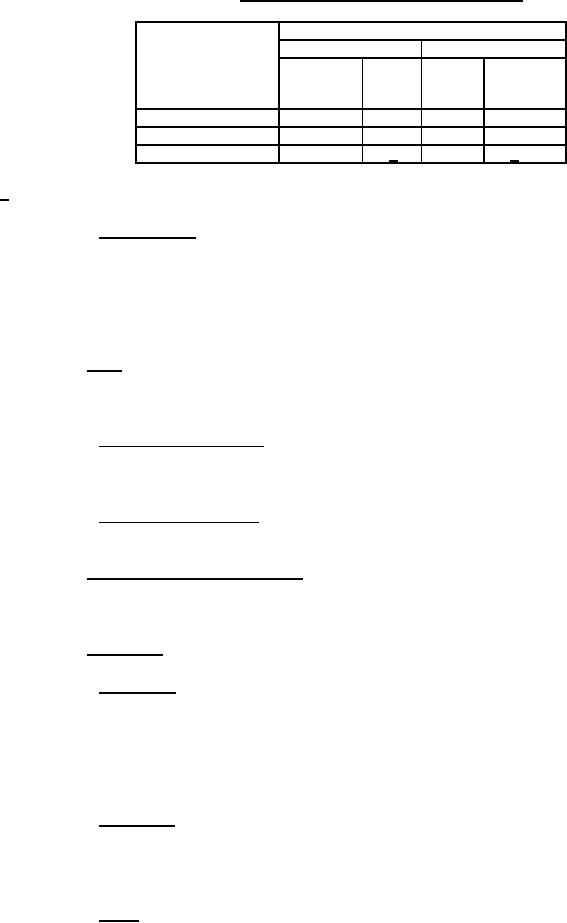

Table II. Length of Staples per Thickness of Boards

Thickness of boards

Length and Gage of Staples

or combined

In boards only

In boards, over wire

thickness of boards,

Length,

Gage

Length, Gage

cleats or battens

inches

inches

(inches)

3/8

1/2

18

9/16

18

3/4 (2 ply 3/8)

7/8

18

1

18

1 1/8 to 1 3/8

1.25

16 1/

1.25

16 1/

Notes:

1/ 1 1/8 length 16 gage permissible into Group IV wood cleats.

3.12.2 Staple spacing. Staples shall be driven at spacing not to exceed 1.75 inches. When the

length of the cleats requires interruption of the nominal spacing, this interrupted space shall not exceed

2.5 inches. The minimum number of staples in any cleat shall be three. At each corner of the box, the

distance from the end of the cleat to the nearest staple shall not be greater than 1 5/8 inches. Staples in

ends shall be driven at a spacing not to exceed 1.75 inches and two staples through ropes as shown in

Figure 1.

3.13 Nails. Nails shall be cement coated or chemically etched cooler, sinker or box type

complying with ASTM F1667. Uncoated nails shall be used in nailing end boards to battens when the

nails pass through the boards and battens and are clinched.

3.13.1 Size and spacing of nails. The size of nails when used for fastening end boards to end

battens shall be 4 penny, 1 3/8 inch long driven at an average spacing of 1.5 inches. Staples used to fasten

end boards to end battens shall comply with 3.12.

3.13.2 Rope handle attachment. For attachment of rope handles, see Figure 1. Deviation from the

nail or staple pattern shall be cause for rejection.

3.14 Box assembly inside dimensions. Inside dimensions shall be specified to the nearest 1/16

inch and shall have a tolerance of +1/8 inch. Compliance with inside dimensions specified on drawings or

in contracts or orders shall be determined on the box assembled as shown in Figure 8A (see 6.5).

3.15 Fabrication.

3.15.1 Wood parts. All parts of the box shall be cut square to size. The grain of wood on top,

bottom and sides shall run lengthwise with the box. Grain of wood in end boards shall run parallel to the

top and bottom cleats. Cleats shall be flush with the ends of the faceboards. Top and bottom boards shall

completely cover the edges of the side boards with a tolerance of minus 1/8 inch on each side. The

maximum allowable gap between faceboards due to mis-manufacture or shrinkage shall not be greater

than 1/4 inch.

3.15.2 Metal parts. Nails or staples not over wire shall be driven so that neither the head nor the

point shall project above the surface of the wood. Occasional overdriving of nails shall be permitted but

none shall be overdriven more than 1/8 the thickness of the piece. Clinched fasteners shall be flush or

below the surface of the container. Fasteners shall be clinched in the thicker board.

3.15.3 Wires. The end of wires forming the loop closures shall be driven through the faceboard

and tightly clinched against the inside surface of the faceboard.

6

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business