MIL-DTL-46506E

3.10.1 Cleats. All cleats shall be mitered. Cleats for Type I, Class 1 and 2 and Type II, Class 1

and 2 boxes shall be made from Group II, III, or IV woods only. Cleat for Type II, Class 3 and 4 boxes

shall be made from Group III and IV only. The thickness and width of cleats shall be as shown in the

applicable figure. A tolerance of + 1/16 inch shall apply to width and thickness of cleats.

3.10.2 Battens. Battens for ends may be made from any group wood. The thickness and width of

battens shall be as shown in the applicable figures. A tolerance of + 1/16 shall apply to thickness of

battens and a tolerance of + 1/8 inch to the width of battens. For Type II boxes, specifying rope handles,

end battens shall be routed for attachment of rope handles as shown in Figure 1.

3.11 Binding wires. Binding wires shall be medium temper low carbon annealed steel wire. Wire

used shall have such physical properties as to permit satisfactory manufacture of loops without fracturing

the wire. The tensile strength shall be from 60,000 to 85,000 pounds per square inch. Splicing or welding

of a binding wire during manufacture is permitted.

3.11.1 Coating. The surface of the wire shall have a regular galvanized coating. The coating shall

be smooth and shall not flake or peel where the wire is bent or twisted.

3.11.2 Diameter of wire. The diameter of all binding wire shall be .092 + .003 inches (13 Gage).

3.11.3 Wire spacing. When possible, the centerline of loop closures shall be spaced equidistant

across the outside length of the box.

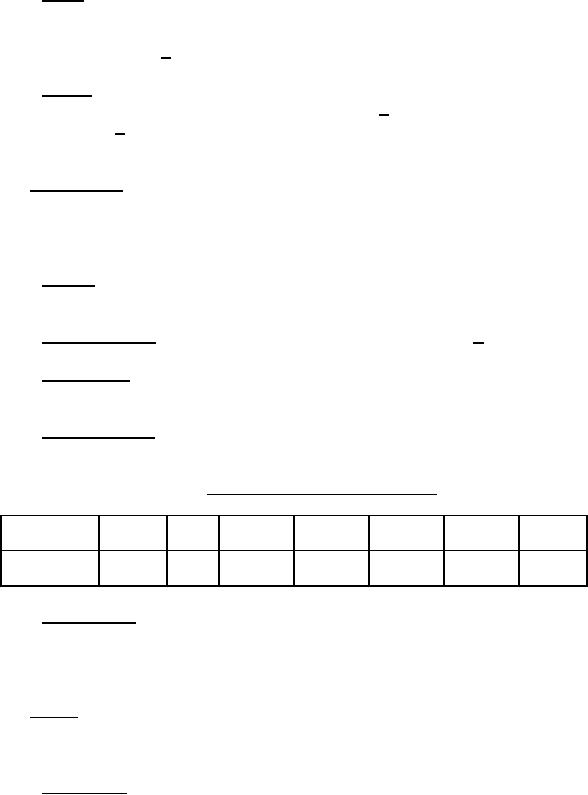

3.11.4 Number of wires. Unless otherwise specified on the applicable drawing, the number of

wires used shall be as specified in Table I.

Table I. Number of wires per length of box

Inside length

Up to 9

9 7/8

14 1/16

27 11/16

36 1/16

42 11/16

50 1/16

box (inches)

13/16

to 14

to 27 5/8

to 36

to 42 5/8

to 50

to 72

Number of

2

3

4

5

6

7

8

wires

3.11.5 Loop closures. Loop closures shall be either the looped wire closure or twisted wire

closure illustrated in Figure 9. The loop, both side and top, shall project beyond the edges of the

faceboard a minimum of one inch. Top loops shall fit over the side loops. Loops shall be produced which

shall provide a tight secure closure when closed by machinery or manually as illustrated in Figure 9.

3.12 Staples. Staples shall be made from hard temper low carbon steel wire and shall have a

regular galvanized coating. The tensile strength of stapling wire shall be from 95,000 to 125,000 pounds

per square inch. Galvanized coating shall be as specified in 3.11.1.

3.12.1 Staples sizes. The staples shall be as specified in Table II. Staples in ends shall be 1 3/8

inches, 14 gage when rope handles are specified. Staples in ends without rope handles shall be 1.25 inch,

16 gage.

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business