MIL-DTL-46506E

PARAGRAPH TITLE

SHEET 2 OF 2

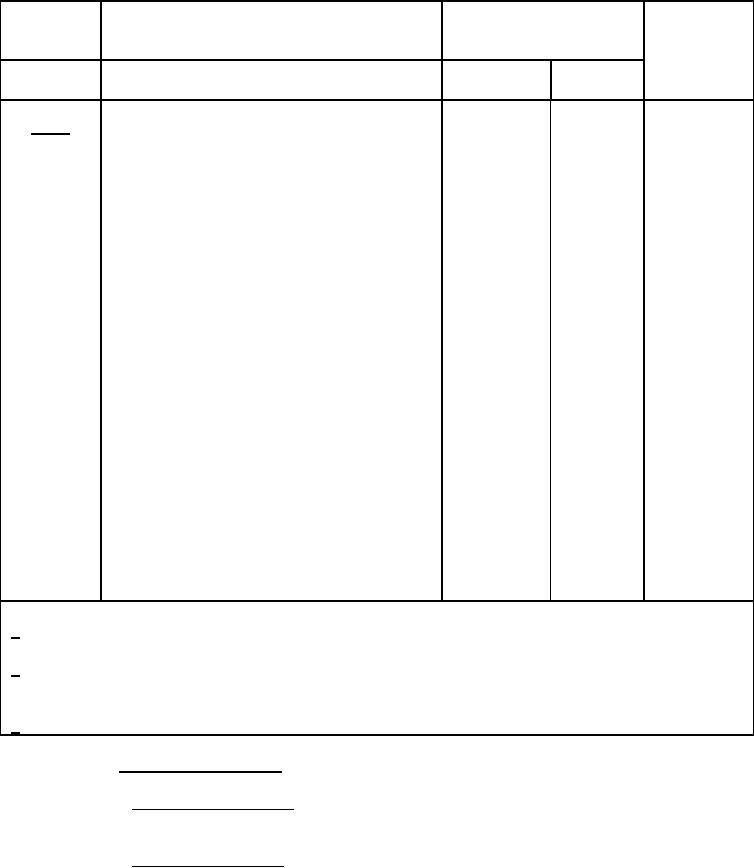

4.2.2

Assembly

INSPECTION

METHOD

Classification

EXAMINATION OR TEST

CONFORMANCE

REQUIREMENT

CRITERIA

PARAGRAPH

Minor

207

Sound knot or cluster of knots larger than 1/3 width of

100%

3.7.1

Gage

wood

208

Sound knot larger than 1/4 width of cleat

100%

3.7.2

Gage

209

Loose knot or knot hole larger than 5/8 inch in diameter

100%

3.7.3

Gage

in faceboards

210

Knots closer than 1 1/4 inch from end of cleat or batten

100%

3.7.4

Gage

211

Diameter of loose knot or knot holes exceeding 1/4

100%

3.7.4

Gage

width or depth of cleat or batten

212

Divergence of grain exceeding 1 inch in 8 inches of

100%

3.8.2

Gage

length

213

Opening between faceboard greater than 1/4 inch

100%

3.15

Visual

214

Cleat extending beyond faceboard surface

100%

3.15

Visual

215

Handle missing, not properly located or of improper

100%

3.13.2

Visual

pattern

216

Marking misleading or unidentifiable

100%

3.21

Visual

217

Broken staples, four or more per intermediate wire

100%

3.12

Visual

218

Nail or staple missing

100%

3.13

Visual

219

Nail or stapling pattern not as required

100%

3.12.2, 3.13.1

Visual

220

Diameter of wire

100%

3.11.2

Gage/ Visual

221

Split full length (more than one for board 4 inches wide

100%

3.6.1

Gage/ Visual

or less, or more than two for board greater than 4 inches

wide)

222

Partial splits (less than 1/3 length of board not more

100%

3.6.3

Gage/ Visual

than 3 in a board)

223

Overall width of faceboard, as applicable

100%

3.9.1

Gage

224

Number of wires

100%

3.11.4

Visual

225

Evidence of poor workmanship

100%

3.22

Visual

Notes:

1/ Select a sample of 15 Grade A boxes at random for this test. Subject four individual boards (cleat, faceboard,

endboard and batten) of each box to the test specified.

2/ Select a sample of 15 boxes at random for this test. Examine the boxes for the presence of pests or evidence

of infestation, for example worm holes. Any visual obvious infestation or evidence of infestation of any box in

the sample lot shall be cause for rejection.

3/ A certification shall be delivered to show compliance with the tensile strength requirement.

4.3 Conformance inspection.

4.3.1 Conformance inspection. The sample boxes shall be subjected to conformance verification

in accordance with 4.3.3.

4.3.2 Conformance rejection. If any sample fails to comply with the conformance inspection

requirements, the lot shall be rejected.

13

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business