MIL-DTL-46506E

4.2 First article inspection. When specified, a sample of sixty-five (65) wooden boxes shall be

subjected to first article inspection in accordance with 4.2.2.

4.2.1 First article rejection. If any item of the sample fails to comply with the first article

inspection requirements, the sample shall be rejected.

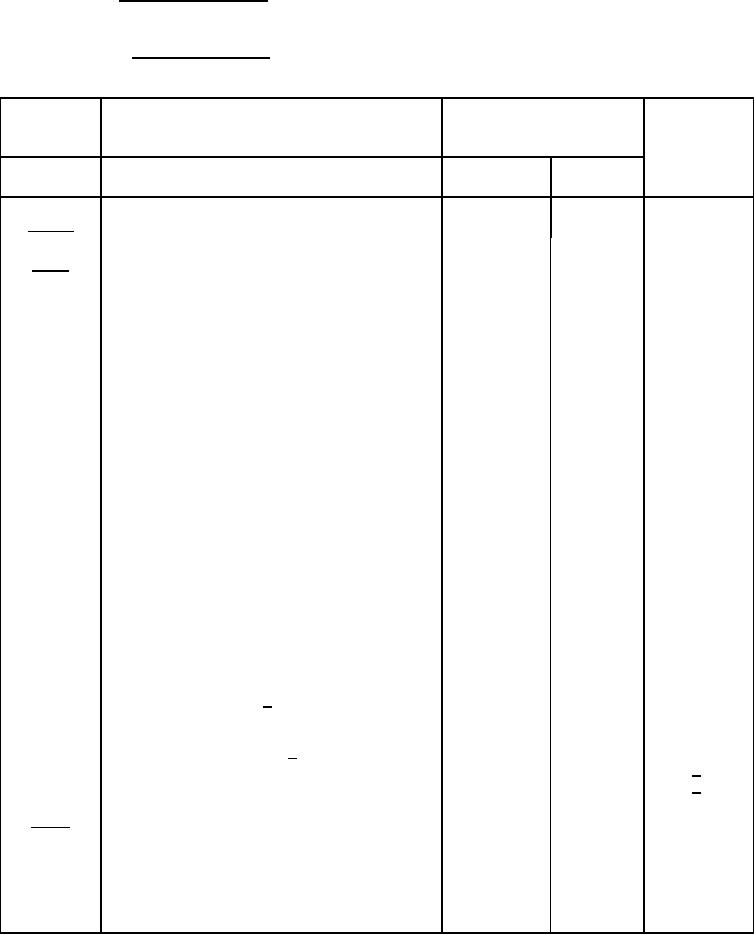

PARAGRAPH TITLE

SHEET 1 OF 2

4.2.2

Assembly

INSPECTION

METHOD

Classification

EXAMINATION OR TEST

CONFORMANCE

REQUIREMENT

CRITERIA

PARAGRAPH

None defined.

Critical

Major

101

Inside length, minimum

100%

3.14

Gage

102

Inside width, minimum

100%

3.14

Gage

103

Inside depth, minimum

100%

3.14

Gage

104

Decay exceeding 1/3 length or affecting serviceability

100%

3.8

Gage

of board cleat or batten

105

Hazardous splinters or sharp edges projecting

100%

3.22

Visual

106

Bulged or buckled wires

100%

3.22

Visual

107

Wood species not conforming to specification

100%

3.3

Visual

108

Board broken cross grain affecting utility of box

100%

3.4

Visual

109

Split full length in cleat or batten

100%

3.6.1

Visual

110

Split forming sliver at edge of board

100%

3.6.2

Visual

111

Top and bottom overlap not less than 1/4 inch

100%

3.15.1

Gage

112

Binding wires broken or missing

100%

3.11

Visual

113

Prong of binding wires not driven into wood

100%

3.15.2

Visual

114

End of wire not clinched

100%

3.15.3

Visual

115

Improper staple size over outer and intermediate wires

100%

3.12.1

Gage

116

Broken staples, four or more per outer wire

100%

3.12

Visual

117

Protruding nails or staple points

100%

3.13

Visual

118

Wire or staples not galvanized

100%

3.11.1

Visual

119

Short loop (preventing closing of box)

100%

3.11.5

Visual

120

Flaking or peeling of galvanized coating

100%

3.11.1

Visual

121

Hazardous splinters, sharp edges protruding, or bulged

100%

3.22

Visual

or buckled wires

122

Preservative treatment not completely dry

100%

3.19

Visual

123

Presence of heat treatment 2/

15

3.20

Visual

124

Load test of handles, rope or webbing

15

3.18.1

4.5.2.1

125

Determination of moisture content

15

3.17

4.5.1

126

Presence of wood preservative 1/

15

3.19

4.5.3, 4.5.4, 4.5.5

127

Binding wire tensile strength

N/A

3.11

3/

128

Stapling wire tensile strength

N/A

3.12

3/

Minor

201

Inside length, maximum

100%

3.14

Gage

202

Inside width, maximum

100%

3.14

Gage

203

Inside depth, maximum

100%

3.14

Gage

204

Thickness of wood

100%

3.9

Gage

205

Width of cleats and battens

100%

3.10.1, 3.10.2

Gage

206

Wane on surface of board excessive

100%

3.8.1

Gage

12

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business