MIL-DTL-46506E

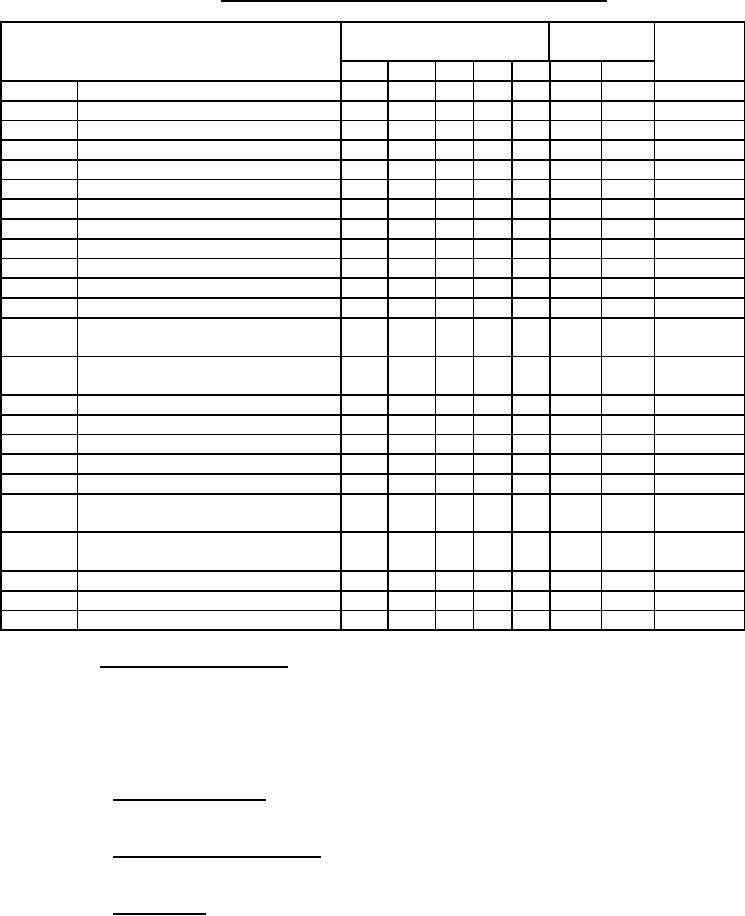

TABLE III. Requirement/verification cross reference matrix continued

Section 3 Requirement

Verification Methods

Verification

Section 4

Class

Method

N/A

1

2

3

4

A

B

3.13.1

Size and spacing of nails

X

X

X

4.3.3

3.13.2

Rope handles attachment

X

X

X

4.3.3

3.14

Box assembly inside dimensions

X

X

X

4.3.3

3.15

Fabrication

3.15.1

Wood parts

X

X

X

4.3.3

3.15.2

Metal parts

X

X

X

4.3.3

3.15.3

Wires

X

X

X

4.3.3

3.16

End boards and end battens

X

X

X

4.3.3

3.17

Moisture content

X

X

X

X

4.5.1

3.18

Handles

X

X

X

X

4.5.2

3.18.1

Load test for handles

X

X

X

4.5.2.1

3.18.2

Jute rope handles

3.18.2.1

Rope handles for 13/16 inch thick

X

X

X

4.5.2.2

batten boxes

3.18.2.2

Rope handles for 1 1/8 inch thick

X

X

X

4.5.2.2

batten boxes

3.18.3

Polypropylene rope handles

X

X

X

X

4.5.2.4

3.18.4

Polyethylene rope handles

X

X

X

X

4.5.2.4

3.18.5

Webbing handles

X

X

X

4.5.2.3

3.19

Preservative treatment

X

X

X

X

4.3.3

3.19.1

Presence of PQ56 preservative

X

X

X

X

4.5.3

3.19.2

Presence of M-GARD W550

X

X

X

X

4.5.4

preservative

3.19.3

Presence of M-GARD W510 or

X

X

X

X

4.5.5

Cunapsol 5 preservative

3.20

Heat treatment

X

X

X

X

4.5.6

3.21

Box identification

X

X

X

4.5.7

3.22

Workmanship

X

X

X

4.5.8

4.1 Classification of inspections. The inspection requirements specified herein are classified as

follows:

a. First article inspection (see 4.2)

b. Conformance inspection (see 4.3)

4.1.1 Verification conditions. Unless otherwise specified, all verifications shall be performed in

accordance with the test methods and conditions specified in section 4.5.

4.1.2 Classification of characteristics. For examinations and tests cited herein or when required

by contract; critical, major, and minor characteristics are defined in MIL-STD-1916.

4.1.3 Lot formation. Lot formation shall be in accordance with MIL-STD-1916.

11

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business