MIL-DTL-3060G (AR)

APPENDIX A

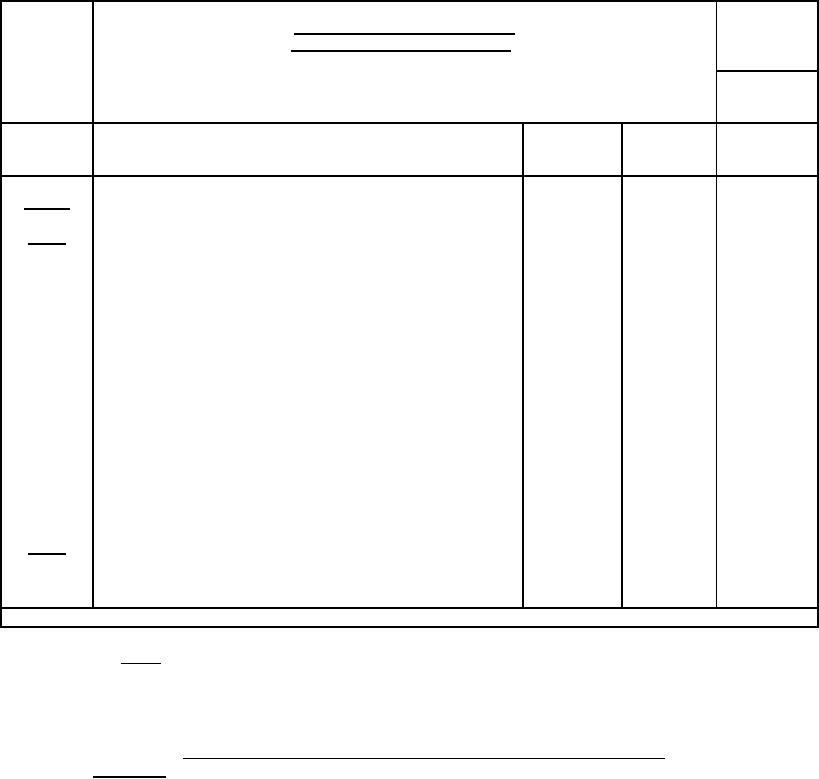

A3.1.2.1

DRAWING

Box, Ammunition, M2A1 Assembly

NUMBER

Box, Ammunition, M19A1 Assembly

7553296 /

7553315

NEXT

HIGHER

ASSEMBLY

Examination or Test

Conformance

Requirement

Inspection

Classification

Criteria

Paragraph

Method

Critical

None Defined.

Major

101

100%

3.5

4.4.4

Airtightness

102

100%

3.5

Visual

Seam weld cracked

103

VL IV

A2.7.1

4.4..1

Paint thickness

104

VL IV

A2.7.1

4.4.1

Paint adhesion

105

VL IV

A2.7.2

4.4.2

Corrosion Resistance

106

VL IV

A2.8.1

4.4.3

Functioning cover assembly

107

VL IV

A2.8.2

4.4.3

Functioning hasp and latch

108

VL IV

A2.8.3

4.4.3

Functioning elevated temperature storage

109

VL IV

A3.7

4.4.6

Gasket compression

110

Dents affecting stenciling, functioning or packing of ammunition or

VL IV

A2.4

Visual/SMTE

dents greater than ¼"

111

VL IV

A2.5

Visual

Cleaning improper prior to priming and painting

112

VL IV

A2.2

Visual

Gasket not replaced properly

113

VL IV

A2.6

Visual

Bare metal not primed prior to painting

114

VL IV

3.3.1

Visual

Paint improper

115

One or more spot or projection welds broken on cover assembly or

VL IV

3.4

Visual

body assembly

Minor

201

VL II

3.4

Visual

Marking on body assembly missing, incomplete or illegible

202

VL II

3.8

Visual

Evidence of poor workmanship

A4. Notes.

A4.1 The renovated container assemblies should be packaged in accordance with dwg.

7553352 or procedures approved by the Government for packaging and palletization.

A4.2 Submission of renovation, inspection, and packaging and palletization of

procedures. The procedures for the renovation, inspection, and packaging and palletization of the

M2A1 Ammunition Box Assembly should be submitted to the Government for approval.

17

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business