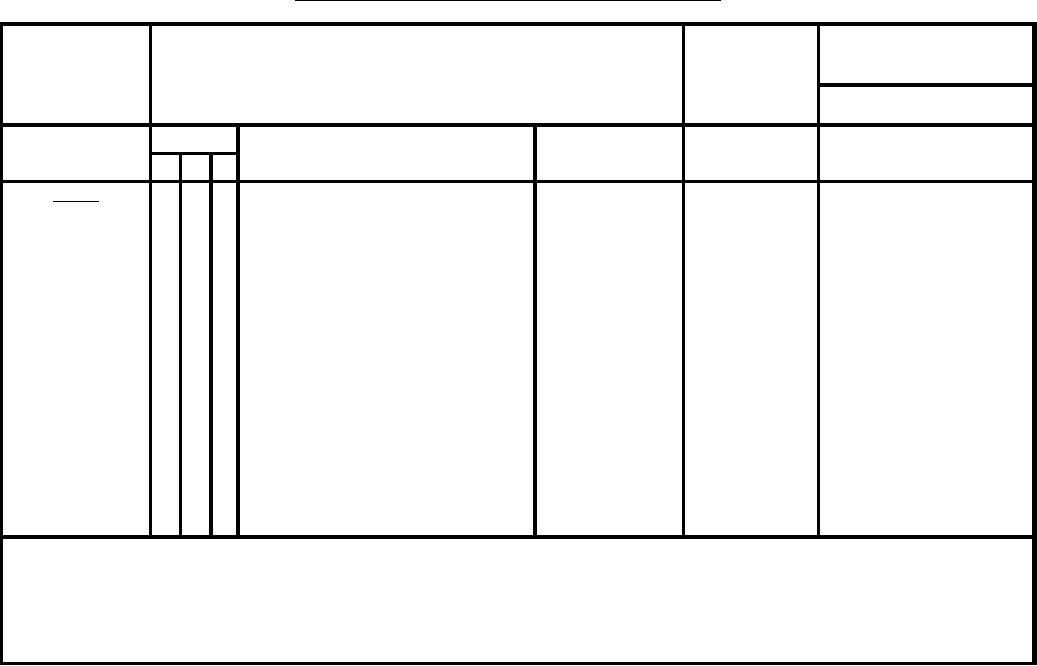

MIL-DTL-2427H (AR)

Conformance inspection by classification of characteristics

PARAGRAPH

TITLE

DRAWING NUMBER

4.3.2.1

Assembly

drawing indicated by

SHEET 5 OF 7

contract

NEXT HIGHER ASSEMBLY

EXAMINATION OR TEST

Grade

CONFORMANCE

REQUIREMENT

INSPECTION METHOD

CLASSIFICATION

A

B

C

CRITERIA

PARAGRAPH

REFERENCE

Minor

213

x

x

x

Overlap of edges incorrect

Level II

3.8.2

SME

214

x

x

x

Cleat extending beyond box surface

Level II

3.8.1

Visual

215

x

x

x

Separator improperly assembled

Level II

See(***)

Visual

216

x

x

x

Separator of incorrect pattern

Level II

See(***)

Visual

217

x

x

x

Nail protruding outside box

Level II

3.8.1

Visual

218

x

x

x

Split in board

Level II

3.3.2

Visual

219

x

x

x

Screw in split or joint between boards

(See Note 5)

Level II

3.5/3.8.1

Visual

220

x

x

x

Handle missing, not properly located,

or of wrong pattern

Level II

3.4

Visual

221

x

x

x

Nail missing

Level II

3.7.3

Visual

222

x

x

x

Nail bent on box surface

Level II

3.8.1

Visual

223

x

x

x

Protective coating damaged (See Note

Level II

3.5

Visual

6)

***. See applicable drawing indicated by contract

Note 5. Hardware screws occurring in a split or in the joint between two boards will have less holding power than screws in a solid board. Screws in splits, whether

caused by the screw or not, and in joints between boards shall be cause to classify the box defective. No repairs are permitted since there is no way to replace the holding

power lost by reason of the defect.

Note 6. When the base metal of the hardware has been exposed or if the action of a corrosive agent has impaired the effectiveness of the protective coating, the box

shall be classified defective.

- 24 -

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business