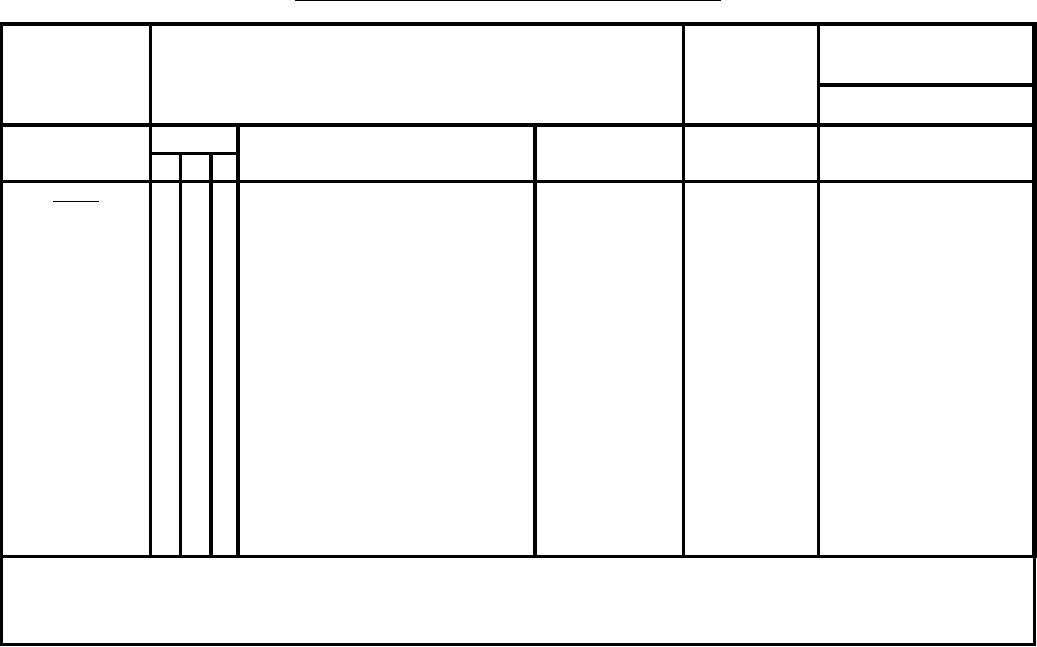

MIL-DTL-2427H (AR)

Conformance inspection by classification of characteristics

PARAGRAPH

TITLE

DRAWING NUMBER

4.3.2.1

Assembly

drawing indicated by

SHEET 2 OF 7

contract

NEXT HIGHER ASSEMBLY

EXAMINATION OR TEST

Grade

CONFORMANCE

REQUIREMENT

INSPECTION METHOD

CLASSIFICATION

A

B

C

CRITERIA

PARAGRAPH

REFERENCE

Major

110

x

x

Acceptable holes, loose knots or knots

surrounded by checking not

sufficiently separated

Level IV

3.3.3

SME

111

x

x

Plugged hole too large

Level IV

3.3.3.1

SME

112

x

x

x

Improper use of board or piece

Level IV

3.6.1/3.6.2

SME

113

x

x

x

Knot holes less than 12 inches apart

Level IV

3.3.3

SME

114

x

x

Solid knot in nailing edge or under

hardware split by nail screw or milling

operation (See Note 1)

Level IV

3.3.3

Visual

115

x

x

x

Nail protruding inside box

Level IV

3.8.1

Visual

116

x

x

x

Grain of wood in wrong direction

Level IV

3.8.1

Visual

117

x

x

Nails not in pattern shown on drawing

or as required by the specification

Level IV

3.7.3

Visual

118

x

x

Split terminating in edge of board

Level IV

3.3.2

Visual

Note 1. Knots in nailing edges or underneath hardware require particular attention. When nails are driven through them, knots may crack or breakout, appreciably

weakening the construction. This sometimes can be corrected by extra wood if nails can be placed in a proper location in solid wood. When such a successful repair is

presented, the box should be considered acceptable. If the attempted repair results in further cracking, however, the box shall be classed defective. Knots in the place of

attachment of hardware often crack sufficiently to loosen the hardware when screws are tightened. Milling operations necessary for the insetting of hardware also often

cause such knots to crack, making proper attachment of the hardware impossible. These two conditions cannot be repaired and the box shall be classed defective.

- 21 -

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business