MIL-DTL-2439F

4.6 Ammunition lot numbers. Ammunition lot numbers shall be visually verified to be in

accordance with MIL-STD-1168.

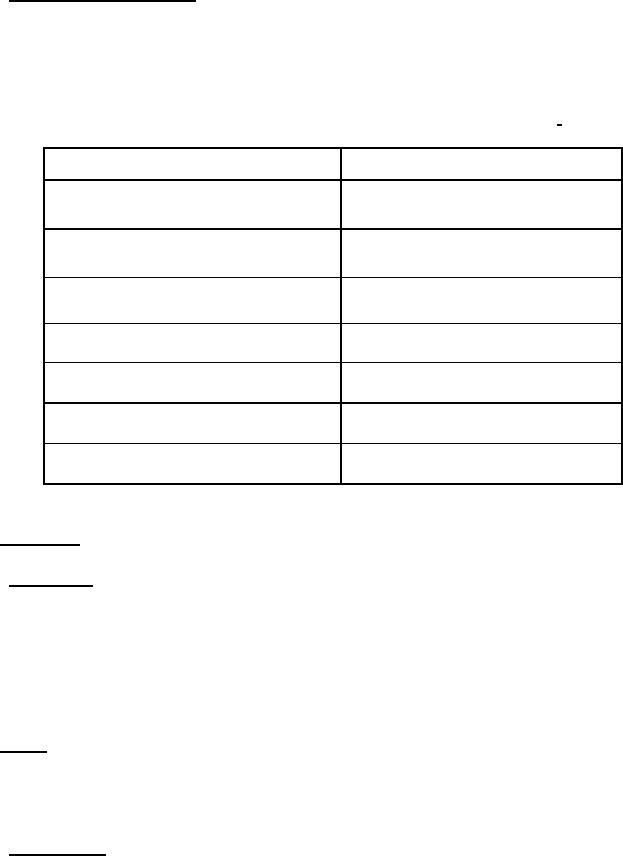

4.7 Polylam and Polycoat material test procedures. Polylam and Polycoat materials shall be

tested in accordance with the specified test method of Table VII.

TABLE VII. Polylam/Polycoat material property test methods.

Property

Test Methos

Vertical (MD) Tear Strength

TAPPI T414

Horizontal (CD) Tear Strength

TAPPI T414

Vertical (MD) Tensile Strength

TAPPI T494

Horizontal (CD) Tensile Strength

TAPPI T494

Mullen Burst Strength

TAPPI T403

Coefficient of Friction

ASTM D 1894

Water Vapor Transmission Rate

TAPPI T523

5. Packaging.

5.1 Packaging. For acquisition purposes, the packaging requirements shall be as specified in the

contract or order, (see: 6.2). When actual packaging of material is to be performed by DoD or

in-house contractor personnel, these personnel need to contact the responsible packaging activity

to ascertain the requisite packaging requirements. Packaging requirements are maintained by the

Inventory Control Point's packaging activities within the Military Service or Defense Agency, or

within the Military Department's or Defense Agency's automated packaging files, CD-ROM

products, or by contacting the responsible packaging activity.

6. Notes.

(This section contains information of a general or explanatory nature that may be helpful but is

not mandatory).

6.1 Intended use. This specification is intended primarily for use in connection with assembly

drawings of fiber containers which are intended for packaging of loaded ammunition items.

Details, supports, specific tube dimensions and requirements for neck ring will be as shown on

the applicable assembly drawings. Dimensions and specific details are to be determined by the

appropriate design agency.

23

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business