MIL-DTL-2439F

4. VERIFICATION

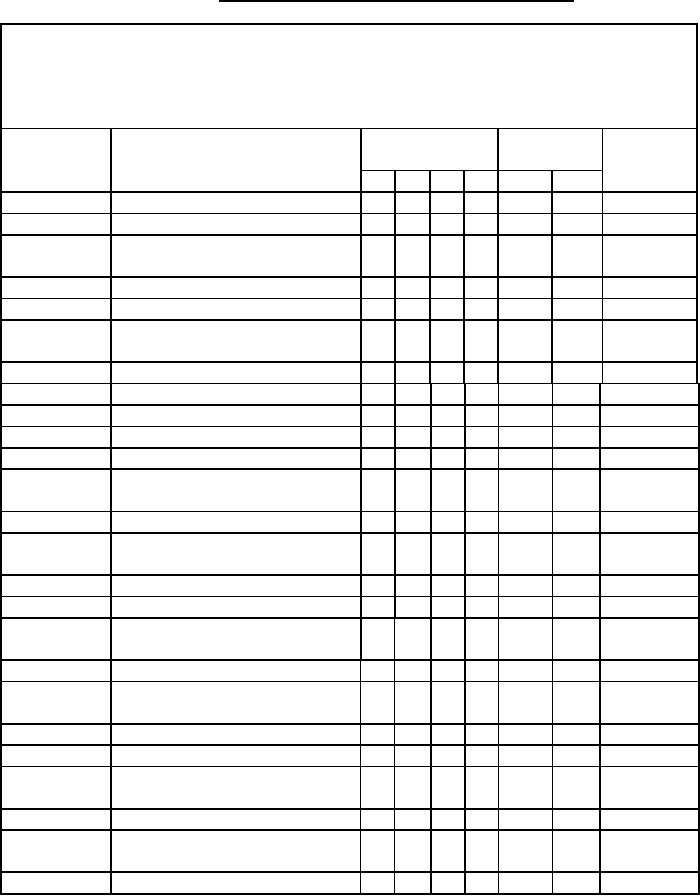

TABLE V. Requirement/Verification cross reference matrix.

Method of Verification

Classes of Verification

1 - Analysis

2 - Demonstration

A - First article

3 - Examination

B - Conformance

4 - Test

Verification

Verification

Section 3

Section 4

methods

class

Description

Requirement

Method

1234

A

B

3.1.1

First article inspection

XX

X

4.3

3.1.2

Conformance

XX

X

4.4

Outer and cover tube

4.4.2.1,

3.2

X

X

X

construction

4.5.1

3.3.1

Neck tube construction

X

X

X

4.5.2.1

3.3.2

Neck tube vent holes

X

X

X

4.5.2.2

Neck tube security

4.4.2.1,

3.3.3

X

X

X

4.5.2.3

3.4

Neck ring

X

X

X

X

4.5.3.1

3.4.1

Neck ring material

X

X

X

X

4.5.3.2

3.4.2

Neck ring plating

X

X

X

X

4.5.3.3

3.4.3

Neck ring corrosion resistance

X

X

X

X

4.5.3.4

3.4.4

Polyester tape

X

X

X

X

X

4.5.3.5

3.4.5

Neck ring workmanship

X

4.4.2.1,

X

X

4.5.15

3.5

Inner tubes

X

X

X

4.5.4

Container cover

4.4.2.1,

3.6

X

X

X

4.5.5

3.7.1

Metal for ends

X

X

X

X

4.5.6.1

3.7.2

Crimping (class 1 and 2 ends)

X

X

X

X

4.5.6.2

Crimp integrity

4.4.2.1,

3.7.2.1

X

X

X

4.5.6.3

3.7.3

Metal end marking

X

X

X 4.4.2.1

4.5.6.4,4.5.

3.7.4

Metal end coating

X

X

X

6.5

3.7.5

Metal end corrosion resistance

X

X

X 4.5.6.6

3.7.6

Domed metal ends

X

X

X 4.4.2.1

Metal end workmanship

4.4.2.1,

3.7.7

X

X

X

4.5.15

3.8.1

Chipboard spacer construction

X

X

X

X 4.5.7

Chipboard spacer drop test

3.8.2

X

X

X

4.5.14.1

resistance

3.9

Polylam material

X

X

4.7

11

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business