MIL-DTL-2439F

3.2 Outer and cover tube construction. The outer and cover tubes shall be spirally wound. For

materials, winding sequence and other details for outer and cover tubes see Figure 1 (Type I, II,

and III containers), Figure 2 (Type IV containers), or Figure 3 (Type V containers). Windings

shall be lapped as shown in Figure 7. Tube windings shall be securely adhered to each other.

No waterproof layer shall be cut in subsequent crimping operations. A hairline of adhesive, not

more than 1/32 inch in width or 1/64 inch in height, shall be permitted beyond the edge of the

outer layer for the asphalt impregnated paper (Types I, II and III containers), the seven point

Kraft paper (Type IV container), or the poly lam layer (Type V container) to which the adhesive

is applied on outer and cover tubes, only.

3.3 Neck tubes.

3.3.1 Neck tube construction. The neck tubes shall be spirally wound. For materials, winding

sequence and details for neck tubes see Figure 4 (Type I, II, and III containers) or Figure 5 (Type

IV containers), or Figure 6 (Type V containers). Windings shall be lapped as shown in Figure 7.

Tube windings shall be securely adhered to each other. No waterproof layer shall be cut in

subsequent crimping operations.

3.3.2 Neck tube vent holes. Neck tubes may be perforated with vent holes as required (see

Figure 8) to provide pressure relief in closing and opening the container. When the exposed

length of the neck tube (portion holding the cap) is less than 2.5 inches, vent holes will not be

required.

3.3.3 Neck tube security. Any adhesive remaining on the exposed exterior surface of the neck

tube, after assembly, shall be removed. Neck tubes, when glued to the outer tube, shall

withstand the torque requirements specified in Table I without movement in the tube.

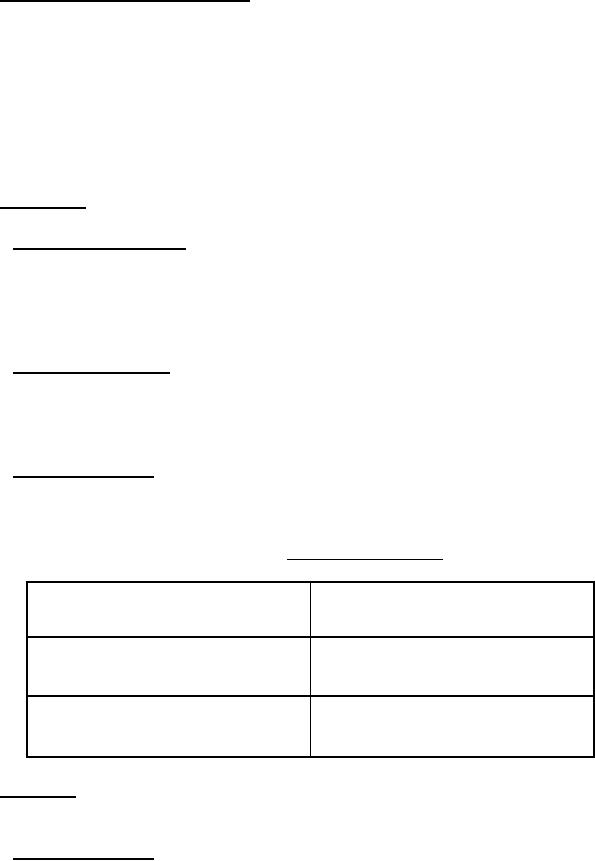

TABLE I. Torque requirements.

Outside Diameter of Outer

Torque to be Applied (Inch-Pounds,

Container

Minimum)

3 inches or less

50

Greater than 3 inches

100

3.4 Neck ring. Neck rings shall also be applied to fiber container neck tubes that open at both

ends, as required. Construction details shall be in accordance with Figure 8.

3.4.1 Neck ring material. All neck rings, including alternate designs, shall be made from 33

gage, minimum, commercial black-plate.

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business